While our dependence on energy storage has rapidly increased, the Lithium-Ion battery today still runs on the same fundamental principles invented in the 1970s. Despite continuous refinement and development, technical progress has slowed. This has led companies to consider other options to continue driving down cost per kWh and increasing energy density.

Solid-state battery (SSB) technology has the potential to transform how we think about energy storage, with applications including electric vehicles (EV), mobile devices, and wearable hardware. The potential upside of effectively commercialized SSB tech has automakers making large bets in the space, most notably with the recent IPO announcement of QuantumScape, a Volkswagen-backed Stanford spinoff. Cost-related challenges, however, have kept SSB technology from becoming commercialized to date.

Despite skepticism about the efficacy and cost of solid-state relative to the traditional Lithium-Ion battery, I predict we will see SSB commercialization as soon as 2023, thanks to a variety of technical hurdles that have recently been overcome. Below, I will lay out many of the technical challenges, drawbacks, and benefits of both Li-Ion and SSB technologies — and explain why I’m bullish on the latter.

Benefits and Challenges of Solid-State Technology

Technically, solid-state technology uses a solid electrolyte to regulate energy flow, rather than the liquid electrolytic solution used in traditional lithium-ion batteries. Using a solid electrolyte provides upside on a number of fronts – higher energy density, longer lifespan, and increased safety are a few aspects that make solid-state technology attractive to EV companies in particular. Notably, higher energy density would dramatically reduce price per kWh, doubling range for EVs and reducing charge times.

This said, the many challenges with solid-state production at scale still leave the technology a few years out from commercialization. Like many new and emerging technologies, solid-state batteries are currently very expensive to manufacture at scale. My conversations with large players building solid-state technology indicate that this expense can be attributed to the cost of materials and the lack of economies of scale in place today (materials and equipment spread across huge supply lines). As a result, heavy doubts remain about SSBs and their mass application in the vehicle and broader energy markets.

Current and Historical Lithium-Ion Progress

Since commercialization in the 90s, Li-Ion batteries have been the industry standard. Three decades later, however, the technology’s intrinsic limitations in terms of safety, performance, form factor, and cost have many in the industry looking toward SSBs for future progress.

As mentioned, most current Li-Ion technologies employ liquid electrolyte, with lithium salts such as LiPF6, LiBF4 or LiClO4 in an organic solvent. This raises inherent size and design freedom limitations, as the liquid electrolyte needs expensive membranes to separate the cathode and anode, as well as an impermeable casing to avoid leakage. The flammable and corrosive liquids add health and safety issues as well.

Advanced Lithium-Ion – Silicon Anodes

However, advanced Li-Ion batteries are more feasible than basic Li-Ion and could potentially rival SSBs in terms of performance. During its recent battery day, Tesla announced its own design of a battery with a pure silicon anode. Relative to other silicon anode concepts, Tesla’s design incorporates the anode expansion issue from the start and utilizes raw silicon metal instead of developing a complicated structure. Tesla has claimed its design, which costs $1.2/kWh, is far cheaper than current solutions. While still ~3 years out from commercialization, this design alone would boost vehicle range by 20%.

While there is less potential upside here relative to SSB players in the EV space such as QuantumScape, many would argue that Tesla’s execution risk is lower relative to the newer, far less mature battery technology.

Regardless, it’s my personal belief that while some improvements can be drawn from basic Li-Ion technology, the next great leaps will be attributed to Solid-State breakthroughs.

The Bounds of Basic Li-Ion

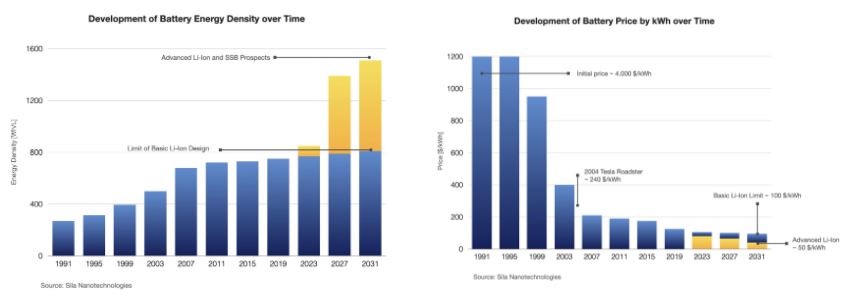

We have reached fundamental physical limits of traditional Li-Ion design; as a result, progress has slowed significantly. The battery of the future will demand the following technical requirements: significantly lower cost (<$100/kWh), lifetime improvements (10,000+ charging cycles), higher energy density (800+ Wh/L), and rapid charge speed improvements.

While advanced Li-Ion designs have the potential to rival SSBs in terms of energy density (Wh/L) and price ($/kWh) in the short term, solid-state energy storage technology is required to break the theoretical limits of Li-Ion efficiency. Best-in-class Li-Ion energy density currently sits at 700 Wh/L and is expected to stagnate at 800 Wh/L due to the characteristics of the technology’s active materials. The goal for solid-state technology is to push the envelope of technical capabilities at 1000 Wh/L, a feat that would democratize EV access and energy storage.

Due to these technical truths and the all-star teams solving the technical challenges at QuantumScape, Sion Power, and others, I’m betting on solid-state technology to be the battery of the future.